You want to sell EMS devices, but so does everyone else. The problem? Most of them look and feel the same. If your product doesn't stand out, your brand won’t either. That’s where customization steps in—to help you break the mold.

You can customize EMS devices by choosing your own design, features, protocols, packaging, and even software. This allows your brand to reflect quality, purpose, and innovation—everything your customer expects.

I’ve worked with many buyers looking for unique EMS devices. Their goal is always the same: “I don’t want just another product—I want my product.” Here's how we help make that happen.

[Table of contents]

Why does customizing EMS devices matter for your brand?

When everyone sells the same product, differentiation becomes your biggest challenge. Customizing EMS devices helps your brand stay relevant, desirable, and competitive.

Customized EMS devices help brands stand out by reflecting unique design choices, user experience, and tailored functionality for specific market needs.

What are EMS devices?

Electrical Muscle Stimulation (EMS) devices send electrical pulses to muscles, causing them to contract. They’re used for fitness training, recovery, pain relief, and rehabilitation.

EMS devices use low-frequency electrical pulses to activate muscle contractions. They’re popular in fitness, recovery, and pain management markets.

Why are brands investing in EMS tech?

More customers want home-based, smart fitness tools. Brands see EMS devices as a way to offer modern, results-driven tech. And the ability to customize makes it even more attractive.

EMS devices align with wellness trends. Customizing them gives brands an edge in quality, experience, and identity.

What customization options are available for EMS devices?

EMS device customization goes beyond logo printing. From design to app integration, you can create something truly your own.

Customization options include logo printing, housing design, software settings, mobile apps, and packaging design.

Private Labeling vs OEM: What’s the difference?

Private labeling means putting your brand on a ready-made product. OEM allows deeper customization—changing parts, features, or even the shape of the device.

| Term | Meaning | Customization Level |

|---|---|---|

| White Label | Generic product with your logo | Low |

| Private Label | Some surface changes (color, logo, packaging) | Medium |

| OEM | Full product changes (hardware, software, design) | High |

Choose private label for fast market entry; go OEM for full control over how your product looks and works.

What design elements can you customize?

You can customize color, material, button style, straps, LED lights, and overall shape. These choices shape how your customers see your product.

Design customization helps make your EMS device reflect your brand’s look and feel—from colors to how it fits in hand.

Can you integrate your own app or software?

Yes. EMS devices can pair with custom apps to control programs, track sessions, and deliver content. You can also set user access levels and data reporting.

Custom apps enhance user experience and build customer loyalty by offering tailored training and tracking.

What about protocols and stimulation settings?

Brands can create unique pulse patterns, intensity levels, and session programs based on target users—athletes, seniors, postnatal moms, etc.

Custom protocols help your EMS device meet different goals, from weight loss to rehab, making it more valuable to niche markets.

How do you find the right EMS device manufacturer?

Finding a reliable factory is crucial. You need someone who understands your vision and can support it from samples to shipment.

Look for manufacturers with EMS experience, in-house design teams, certifications, and good communication skills.

What should you look for in a factory partner?

Start by checking their certifications, production capacity, and sample quality. Then look at their project management and responsiveness.

| Criteria | What to Check |

|---|---|

| EMS Experience | Previous EMS or TENS product lines |

| Certification | ISO13485, CE, FDA |

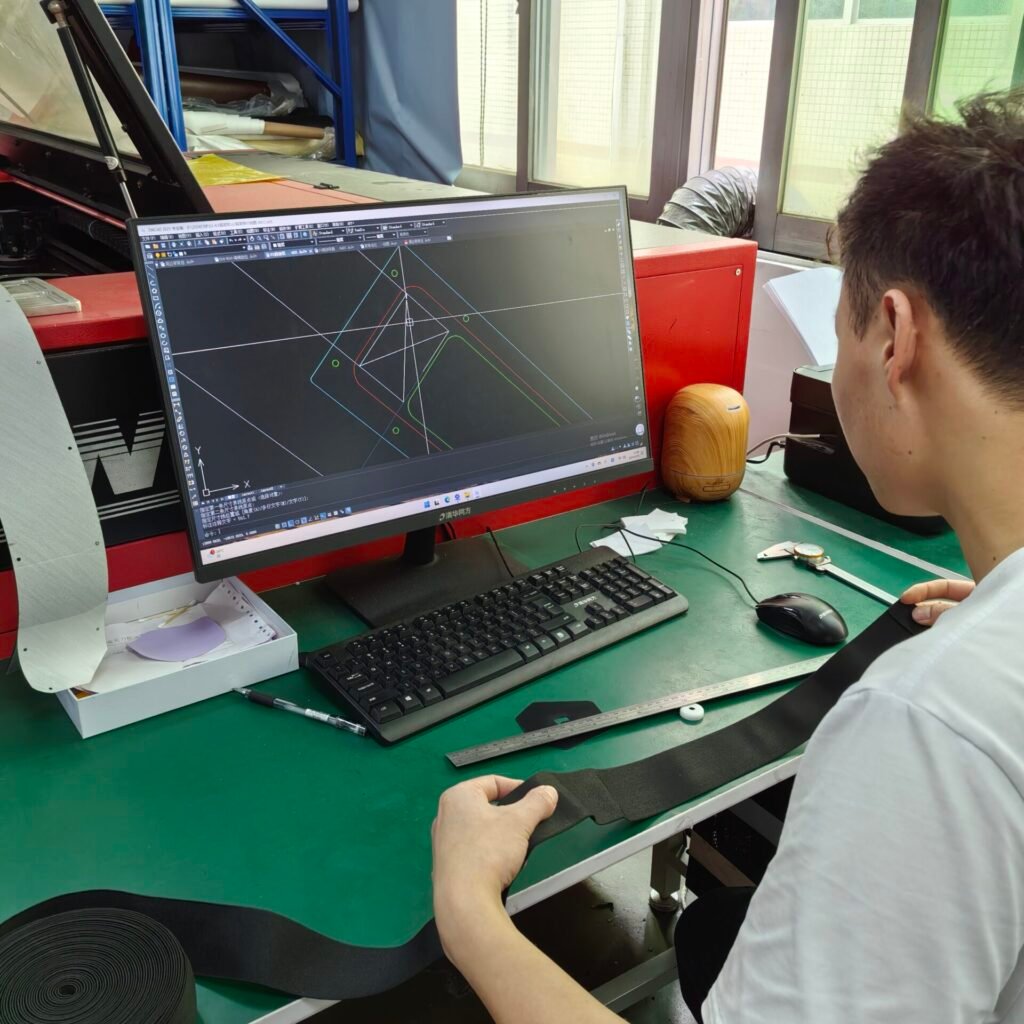

| Design Support | In-house design, mold customization |

| Lead Time | Realistic production & shipping timelines |

| Communication | Clear, fast, and professional |

What questions should you ask before signing?

Ask about mold fees, tooling ownership, MOQ, warranty policies, and compliance documents. Also ask if they’ve worked with brands like yours.

Asking the right questions protects your timeline, budget, and brand vision.

What compliance factors should you consider?

Health-related devices are regulated. You must ensure your product is legal and safe for sale in your target market.

You need certifications like CE for Europe, FDA for the US, and ISO13485 for quality assurance.

What certifications do you need?

It depends on your region. Most markets require CE, FDA, or similar marks for electric health products.

| Region | Required Certifications |

|---|---|

| USA | FDA, ISO13485 |

| Europe | CE, RoHS |

| Japan | PSE, Medical Device certification |

| Korea | KC mark |

Why are testing and documentation important?

Testing proves your device is safe. Documentation protects you from liability and builds trust with distributors and retailers.

Proper testing and paperwork reduce legal risks and reassure your clients.

How can you market your customized EMS device?

Once you’ve built your product, you need a strong launch plan that matches your brand identity and connects with your audience.

Brand story, packaging, and go-to-market strategy all work together to make your EMS device desirable and trusted.

How do you build a brand story?

Start with why your product exists. Is it for busy moms? Pro athletes? Position the product emotionally and practically.

A clear brand story connects with buyers emotionally and builds product trust.

Why does packaging matter?

Great packaging signals quality. Unboxing is now part of the customer journey—and it’s a marketing moment you control.

Premium packaging boosts brand value and repeat sales.

What are some go-to-market strategies?

You can sell via trade shows, B2B marketplaces, or direct to distributors. You can also bundle with training programs or fitness gear.

Go-to-market strategies depend on your audience—think about where they are and how they buy.

Conclusion

Customizing EMS devices helps your brand stand out and grow. With the right partner and strategy, you can create a product that’s truly yours.

FAQs

Can I customize both hardware and software?

Yes. Most manufacturers offer both design and software customization options.

How long does OEM production take?

Typically 30–60 days after sample approval, depending on complexity.

Do I need FDA and CE for every market?

Not always. It depends on your target market. But having both makes your product easier to sell globally.

Is MOQ high for OEM orders?

It varies. Many factories offer low MOQs for testing, with scale-up later.

Can I visit the factory before ordering?

Yes. Visiting the factory can help build trust and clarify the process.