Partnering with the right EMS device manufacturer can feel overwhelming. But without a solid partnership, delays, quality issues, and miscommunication can damage your business.

To build a successful partnership with your EMS manufacturer, focus on clear communication, shared goals, and strong quality standards. This ensures smoother operations, better products, and long-term growth.

Let’s explore how understanding the EMS industry, prioritizing partnership values, and choosing the right manufacturer can set you up for success.

What should you know about EMS device manufacturing?

Before you choose a partner, you need to understand how EMS manufacturing works. This helps you align expectations and spot potential gaps.

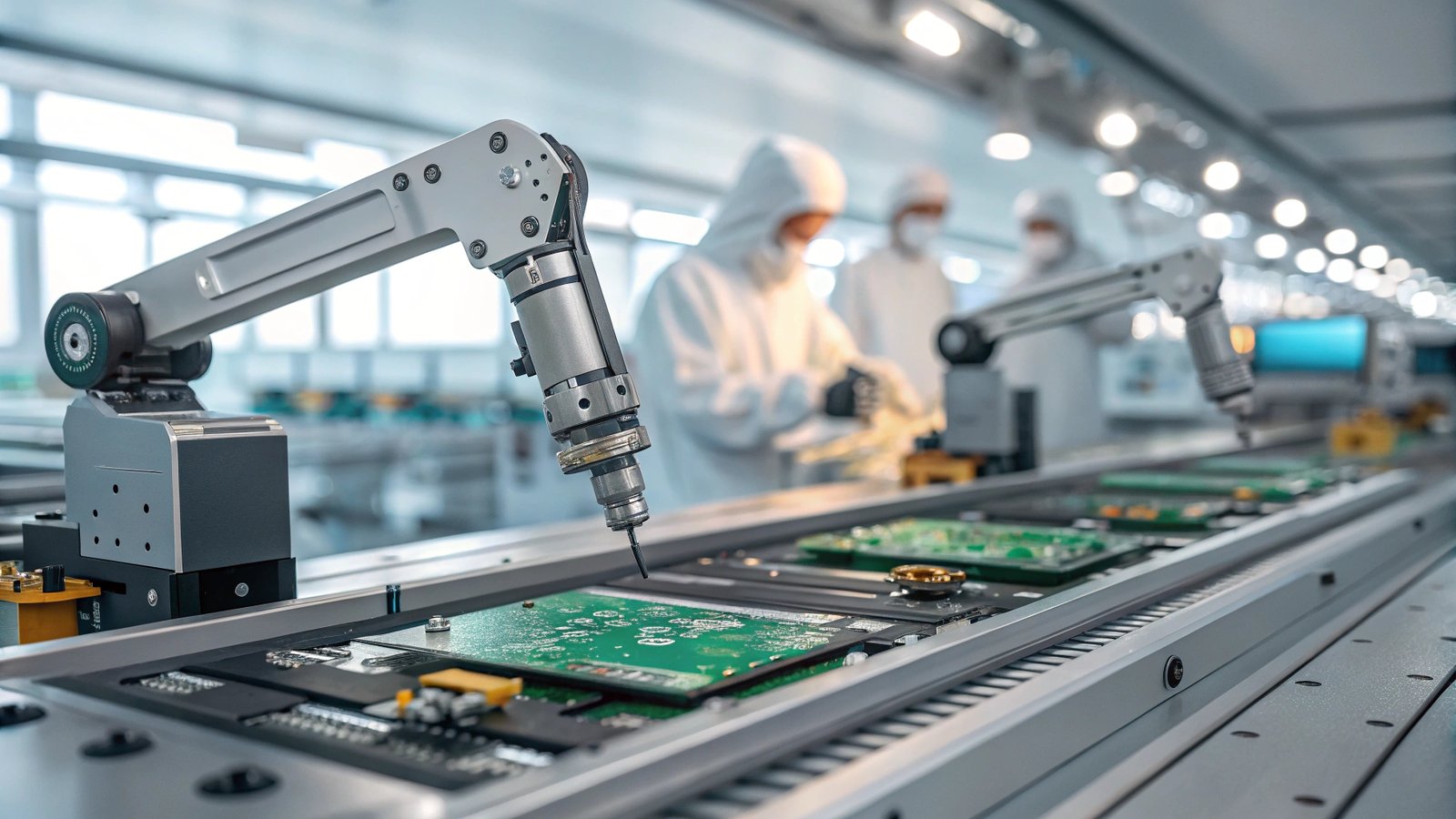

EMS device manufacturing involves developing, assembling, and testing devices that use electrical muscle stimulation (EMS) technology. Manufacturers play a key role in product innovation, customization, and quality assurance.

What is the role of EMS manufacturers in product development?

Your manufacturer is more than just a supplier. They are your partner in bringing innovative EMS products to market.

EMS manufacturers support product design, component sourcing, assembly, testing, and certification. They ensure your device meets safety and performance standards.

EMS manufacturers help refine prototypes, recommend cost-saving materials, and ensure compliance with global regulations like FDA or CE. This partnership helps avoid costly redesigns and ensures faster time-to-market.

Why does a strong partnership with your EMS manufacturer matter?

A good partnership isn’t just about products—it’s about shared success. Working well with your EMS manufacturer impacts every part of your business.

A strong EMS manufacturer partnership boosts product quality, speeds up delivery, and improves market competitiveness. It helps avoid delays and ensures compliance.

What are the benefits of collaboration for product success?

Collaboration leads to better results. You get more than just a product; you gain insights and innovations.

Collaboration ensures your EMS products meet market needs, stay ahead of trends, and maintain high standards.

A cooperative relationship encourages problem-solving and innovation. For example, manufacturers might suggest material upgrades or design tweaks that lower costs or improve performance.

What are the risks of poor manufacturer relationships?

A weak relationship with your manufacturer can hurt your business.

Poor communication or trust can lead to delays, product failures, or non-compliance with standards. This impacts your brand and bottom line.

A lack of alignment can cause missed deadlines, especially during peak sales seasons. Worse, if quality control fails, it can result in recalls or reputational damage.

What are the key elements of a successful EMS partnership?

Successful partnerships don’t happen by accident. They are built on clear expectations and shared values.

Key elements include clear communication, transparency, quality control, and flexibility to adapt to changing needs.

How important are clear communication and expectations?

Misunderstandings cause delays and mistakes. Clear communication solves this.

Both parties should set clear timelines, responsibilities, and expectations to ensure smooth collaboration.

Regular meetings, shared documentation, and defined roles help avoid confusion. Tools like project management platforms can also keep things on track.

Why is transparency in pricing and processes essential?

Surprises in cost or processes create mistrust.

Transparent pricing and process details build trust and help both sides manage costs and timelines effectively.

Request itemized quotes and clarify production timelines. This ensures no hidden fees and allows you to plan your budget and logistics better.

Why do quality control and compliance standards matter?

Skipping quality checks can lead to failed products and legal issues.

Strong quality control and adherence to compliance standards ensure your EMS products are safe and effective.

Look for manufacturers with certifications like ISO 13485, CE, or FDA registration. This shows they meet global quality standards.

How does flexibility and scalability affect your partnership?

Your business will grow, and your manufacturer should grow with you.

A flexible manufacturer can adjust production volumes and timelines based on your business needs.

Discuss scalability options early. Can they handle urgent orders or expand production if demand increases? Flexibility prevents bottlenecks.

How can you choose the right EMS manufacturer?

Finding the right manufacturer is crucial for long-term success. But how do you choose?

Focus on their experience, technology, logistics support, and commitment to quality. These factors ensure reliable partnerships.

How do you evaluate a manufacturer’s experience and expertise?

Experience shapes capability. You want a manufacturer who understands EMS products.

Check their track record, client list, and case studies to assess their expertise in EMS manufacturing.

Ask about past projects, especially those similar to yours. Look for manufacturers who understand your market’s requirements.

How do you assess technological capabilities?

Technology drives innovation and efficiency.

Evaluate their production equipment, R&D capabilities, and ability to support product customization.

Tour their factory or request detailed photos. Ask about their latest production technologies and whether they invest in ongoing upgrades.

Why is understanding supply chain and logistics support important?

A great product needs smooth delivery.

Ensure your manufacturer can handle logistics, from material sourcing to timely delivery, including documentation and customs.

Discuss their logistics partnerships, shipping timelines, and experience with international trade compliance. A strong logistics setup reduces delays.

Conclusion

A successful EMS partnership depends on clear communication, shared goals, and strong quality controls. Choose a manufacturer who aligns with your business needs and can grow with you.